These days it would seem as if

every product were manufactured with an engineered lifespan. I find this

particularly true with cheaper electronics. Parts and components of a unit

typically fail at what seems suspiciously close to mere weeks after a warrantee

period has ended. For some, this equates to the slow sad procession of obsolete

electronics to the curb on trash night. To others like me, it lends an

opportunity to open a unit up to see if something could be repaired or at least

harvested for parts.

Case in point, my father gave me an

old surround sound decoder he no longer wanted. I had purchased him a sound bar

which better suits his needs and he simply wanted to discard the old decoder. I

had asked him if it worked, and he said that it did but that it made a “funny

noise”. Not deterred, I took it home and opened it up.

Once the

cover was off, nothing seemed out of the ordinary. Typically, the first thing I

look for is any signs of stress or wear on the components. None of the

capacitors looked swollen and there were no observable burn marks or loose

solder joints. So, at first glance everything seemed ok.

The next

thing I did was hook the speakers up, apply power to the DUT (device under

test) and then listen for or smell if anything seemed out of place. No sparks,

or smoke erupted when power was applied. Furthermore, nothing seemed to burn or

smell different. The speakers had a very slight hiss to them when the volume

was turned up, so nothing with them sounded like a “funny noise”.

There was, however, a guttural whirling that emanated from

the DUT. On closer inspection it appeared that the fan was struggling to spin.

“Ahh this must be the problem!”, I thought. That seemed like a simple enough

fix. Maybe even a quick blast of air could remedy things.

I popped the fan out of the DUT and gave it a good blast of air. I noted that as per the label the fan ran on 12 volts, so I decided to hook it up to a power supply to ensure that the fan was still in working order. I dialed up the voltage on the power supply and the fan snapped to life with vigor. It ran a little loud, but it moved the air just fine. I was confident that the issue had been resolved and replaced the fan in the DUT.

I

disconnected the fan and read the voltage with a multimeter at the connection

point. It was a little over 8 volts. “Well, that is not 12 volts so that HAS to

be the problem.”, I thought to myself.

At this

point I was a little over my head. Somewhere, I imagined there had to be bad

components buried in the complex circuitry of the DUT. I searched with no

success to find a schematic. I attempted to look at the traces on the board to

get some sense of where to look next. Ultimately, I just started to randomly

probe around looking for 12 volts on the board.

When

none of this worked, I decided to enlist the help of fellow club member Chris Prioli,

AD2CS. He informed me that he would be happy to take some time and look at my

problem.

More

often than not, there is always something going on at the clubhouse every

Saturday. Whether it is a Tech Saturday presentation, the satellite station

flexing its muscles on the newest satellite deployed or restoring the clubhouse

to better than former glory. The activity there is both welcoming and

productive. This was the perfect place to meet up with Chris, and to get some

use out of the clubhouse’s test bench.

I met up

with Chris early on Saturday morning and after a few moments of discussing

Chris’ latest project we moved to the test bench to diagnose my issue. I

explained the problem that the DUT was experiencing to him. He then did a quick

search for a service manual to no avail.

We also removed the board in question and did a visual examination, nothing

seemed out of place.

Next, we hooked the DUT up to the

test benches’ isolated AC power supply. This was an interesting piece of test

equipment that isolates any circuit powered by it from AC mains. It also had

the ability to adjust the voltage so that a user can slowly increase the

voltage up to the recommended value. The DUT powered up normally and when

turned on via the front panel switch, the fan began to intermittently spin.

Up to

this point the steps taken were nearly identical to what I had performed in my

earlier analysis. Chris, however, took a different approach when he checked the

voltage being delivered to the fan. Instead of using a multimeter he opted to

use the oscilloscope instead. I asked about this and he informed me that the

“scope” could give us much more information about the voltage than merely its

value. For instance, it can tell us if it is flat or alternating in any form

over time. For the DUT it appeared that the voltage was a flat DC value a

little more than 8 volts. This led us to believe that the voltage being

delivered was probably not the issue since it was constant, with little to no

ripple in it.

Chris

had me remove the fan again, and he visually inspected it. “Look here.”, he said to me while spinning

the fan blades with his finger. He continued, “The fan does not spin smoothly,

there is some resistance”, while flipping the power switch of his custom

battery eliminator. This is a piece of test equipment that Chris had built of

his own design. It allows a user to flip through a series of DC test voltages

that are common battery voltages. We started low at 1.5 volts and gradually

increased. The fan started to intermittently turn at around 8 volts and finally

started spinning consistently around 12 volts.

Then it occurred to me that DC fans

should ideally start spinning with low voltage and gradually get faster, NOT

run intermittently. It seems like an obvious enough thought, but it had indeed

eluded me, with my limited experience in troubleshooting. So, my original impression

that the fan was the issue was correct and Chris agreed.

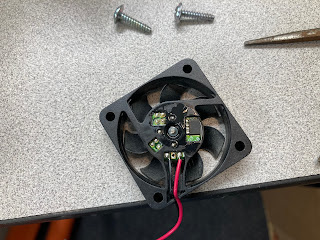

Rather than order a new fan, Chris wanted to see if we could restore the operation of the fan under test. He peeled off the label on the back of the fan to expose the electronics and bearing. He then used component cleaner and compressed air to dissolve and blow out any dirt in the moving parts. Finally, we hooked the fan up to a voltage source to get it spinning and we applied oil to the bearing. Now the fan spun smoothly as soon as voltage was applied. We reinstalled the fan and the DUT now had no issues.

There were a couple of different

ways that I could have addressed the problem. I could have scraped the unit for

parts, or I could have merely ordered a new fan, waited for its arrival and installed

it. Either would have worked out for me, but I feel that it would have wasted the

opportunity to learn and collaborate with fellow enthusiasts. After all, isn’t

that what being in a club is all about?